Have you ever wondered how hydraulic machines control their powerful movements? The secret lies in simple but essential components called valves. Today, we'll explore one of the most basic yet important types: the 2-way hydraulic valve.

What is a 2-Way Valve?

A 2-way valve is essentially an on/off switch for hydraulic fluid. Just as a light switch has two positions (on and off), a 2-way valve has two states: open or closed. When it's open, hydraulic fluid flows through. When it's closed, the fluid stops completely.

Picture a simple gate controlling water flow - when open, water passes through; when closed, flow stops entirely. This basic principle makes 2-way hydraulic valves perfect for controlling fluid movement in hydraulic systems.

Key Features of 2-Way Valves

- Two ports: One inlet (where fluid enters) and one outlet (where fluid exits)

- Two positions: Fully open or fully closed

- Binary control: It's either on or off - no in-between

- Reliable operation: Simple design means fewer things can go wrong

How Does a 2-Way Hydraulic Valve Work?

The working principle is surprisingly straightforward. Inside the valve, there's a moving part called a valve core. This core can be a ball, disc, or sliding piece called a spool.

Two Main Types of Operation

- Default position blocks fluid flow

- When activated (by electricity, air pressure, or manual force), it opens

- Most common in safety applications where you want flow stopped by default

- Default position allows fluid flow

- When activated, it closes the flow

- Useful when you need continuous flow with occasional stopping

What Makes It Move?

The valve core moves through different methods:

- Manual operation: You turn a handle or push a lever

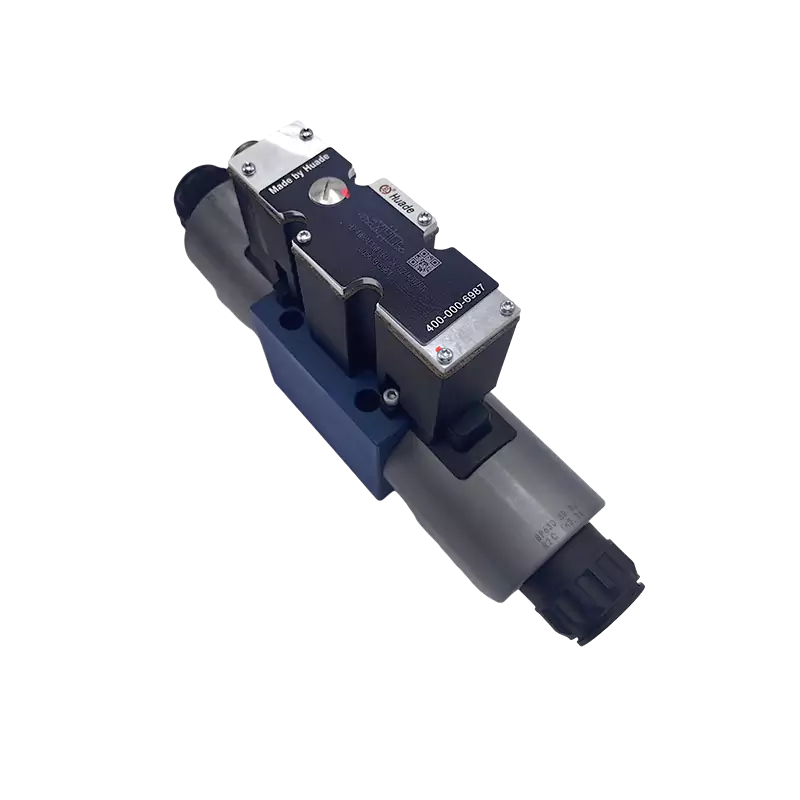

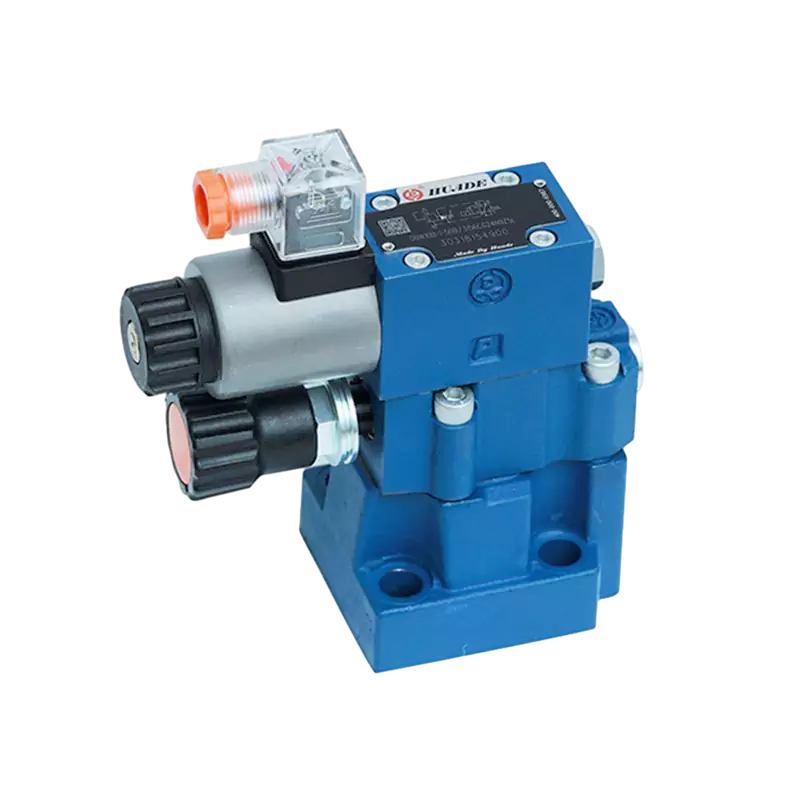

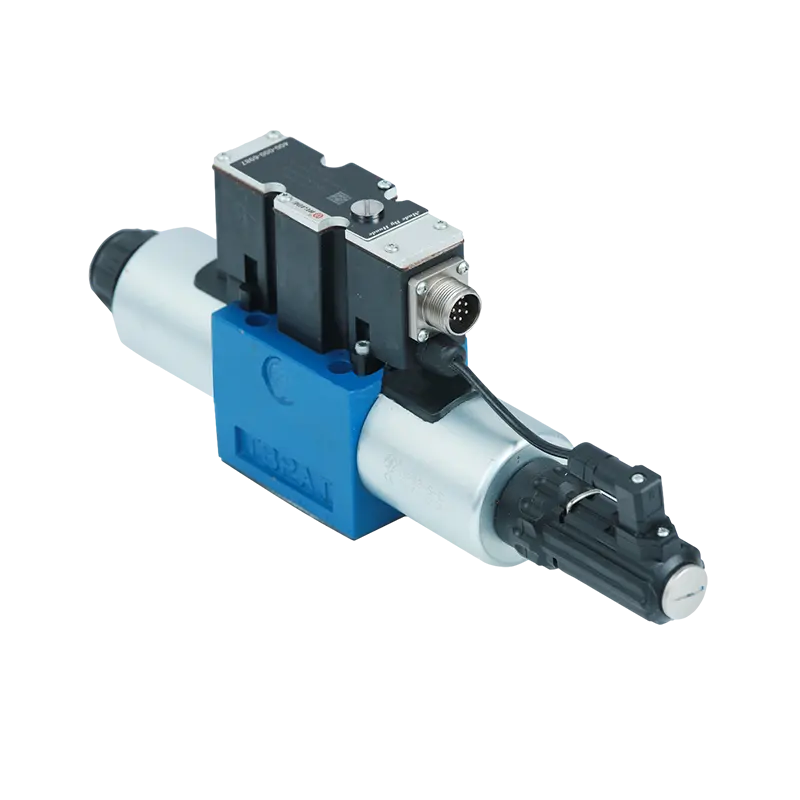

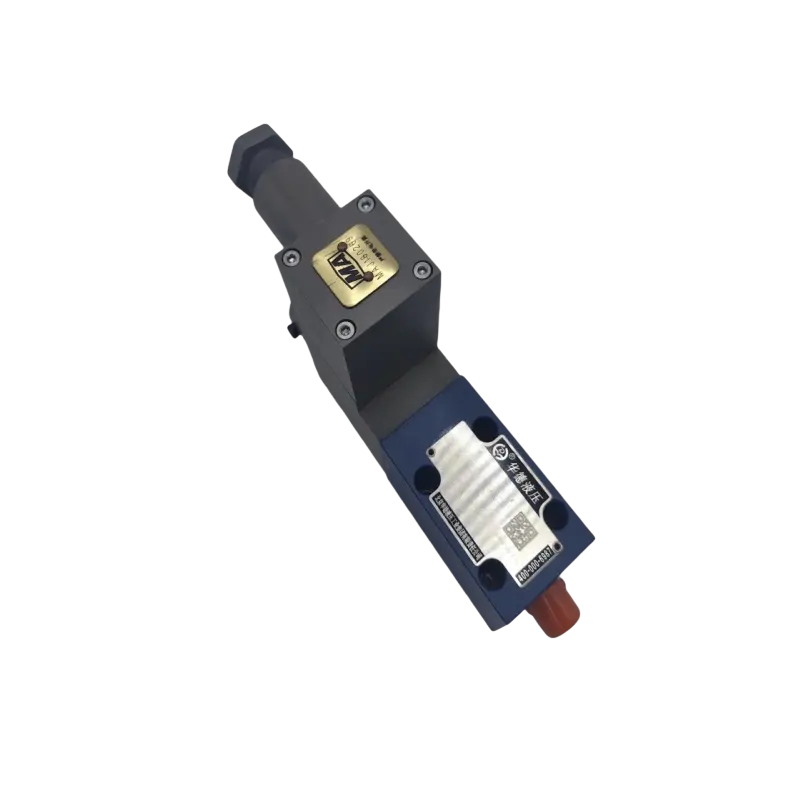

- 2-way hydraulic solenoid valve: An electric coil creates magnetic force for automated control

- Pilot operation: Uses the system's own pressure to move the valve

- Pneumatic operation: Uses compressed air pressure

Types of 2-Way Hydraulic Valves

Understanding different valve types helps you choose the right one for your application.

1. Poppet Valves

Poppet valves use a disc or cone that sits against a seat, creating a tight seal when closed.

Advantages: Almost zero leakage when closed, Fast response time, Works well in dirty environments, Long lasting

Disadvantages: Needs more force to operate, Can be affected by back pressure

2. Spool Valves

Spool valves use a cylindrical piece that slides back and forth inside a sleeve.

Advantages: Easier to operate (needs less force), More balanced operation, Can handle complex flow patterns

Disadvantages: Some fluid leakage, More sensitive to dirt and contamination, Needs more maintenance

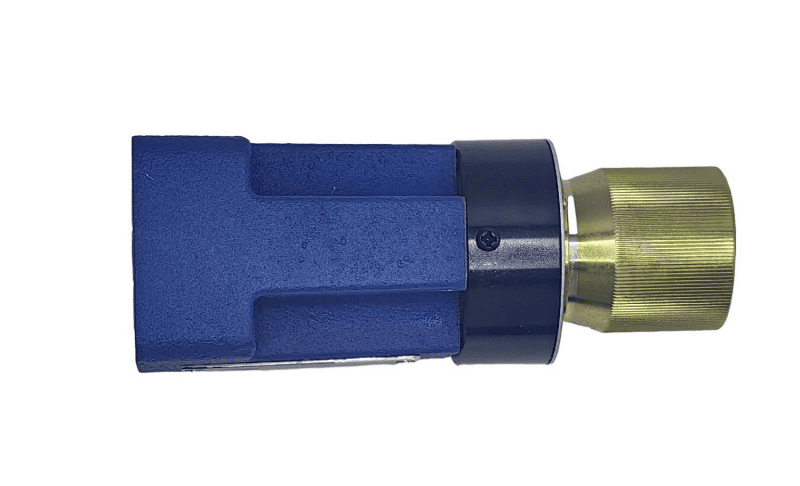

3. Cartridge Valves

These are modular valves that fit into standardized blocks, offering compact installation and high performance.

Advantages: Very compact design, Can handle high flow rates and pressures, Low pressure drop, Standardized mounting

Disadvantages: Needs additional pilot valve to work, More complex installation

2-Way Valve vs 3-Way Valve vs 4-Way Valve

Understanding the differences helps you choose the right valve type for your hydraulic system.

| Valve Type | Ports | Function | Best Applications |

|---|---|---|---|

| 2-Way Valve | 2 | Simple on/off control | Isolation, basic cylinder control, safety shutoffs |

| 3-Way Valve | 3 | Divert or mix fluids | HVAC systems, mixing applications, T-connections |

| 4-Way Valve | 4 | Control double-acting cylinders | Complex machinery, bidirectional motors, advanced control |

Simplest design (fewer parts mean higher reliability), Most economical (lower initial cost and maintenance), Easy troubleshooting, and Versatile applications.

Where Are 2-Way Valves Used?

- System Safety and Isolation: Act as safety guards to quickly stop fluid flow during emergencies or maintenance.

- Flow Control and Regulation: Using pulse-width modulation to precisely control fluid amount.

- Hydraulic Cylinder Control: Controlling single-acting hydraulic cylinders (e.g., dump truck beds).

- Energy Saving: Redirecting pump flow back to the tank when the system is idle.

Industry Applications

- Automotive: Fuel injection, emission control

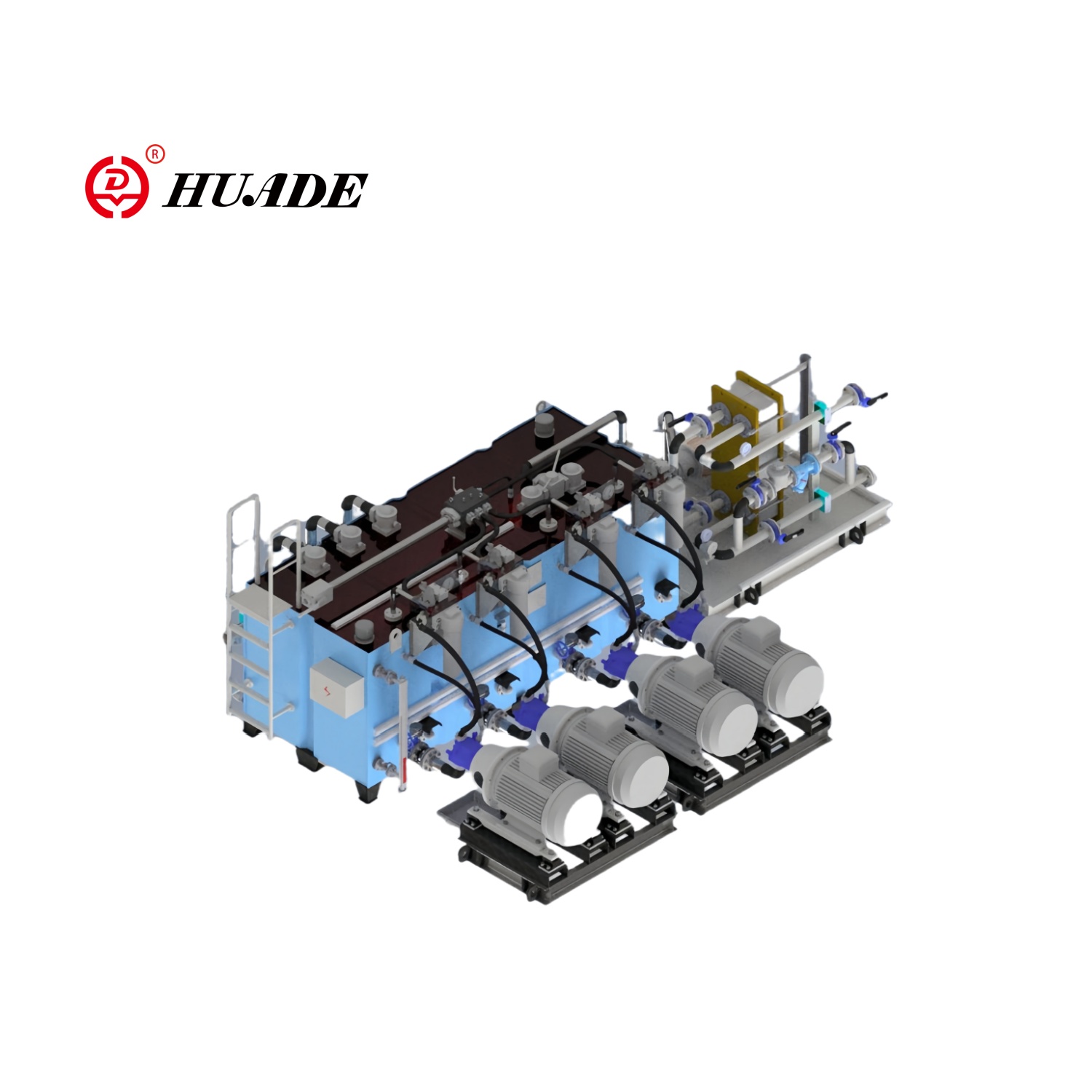

- Construction: Excavators, loaders

- Manufacturing: Assembly lines, presses

- Agriculture: Tractors, irrigation

Understanding Hydraulic Symbols

In hydraulic diagrams, 2-way valves are shown with specific symbols:

- Two boxes represent the two positions (open and closed)

- Arrows show flow direction

- "T" symbols show blocked ports

- Springs and solenoids are drawn on the sides

How to Choose and Maintain

Selection Criteria

- Consider Flow and Pressure: Check Flow coefficient (Cv), Pressure rating, and Port size.

- Response Time: Solenoids are fast (<10ms), Pilot valves are slower but handle high pressure.

- Fluid Compatibility: Ensure materials work with mineral oils, synthetic, or water-based fluids.

- Environmental Conditions: Temperature, dust, moisture, and explosion-proof requirements.

Common Problems & Maintenance

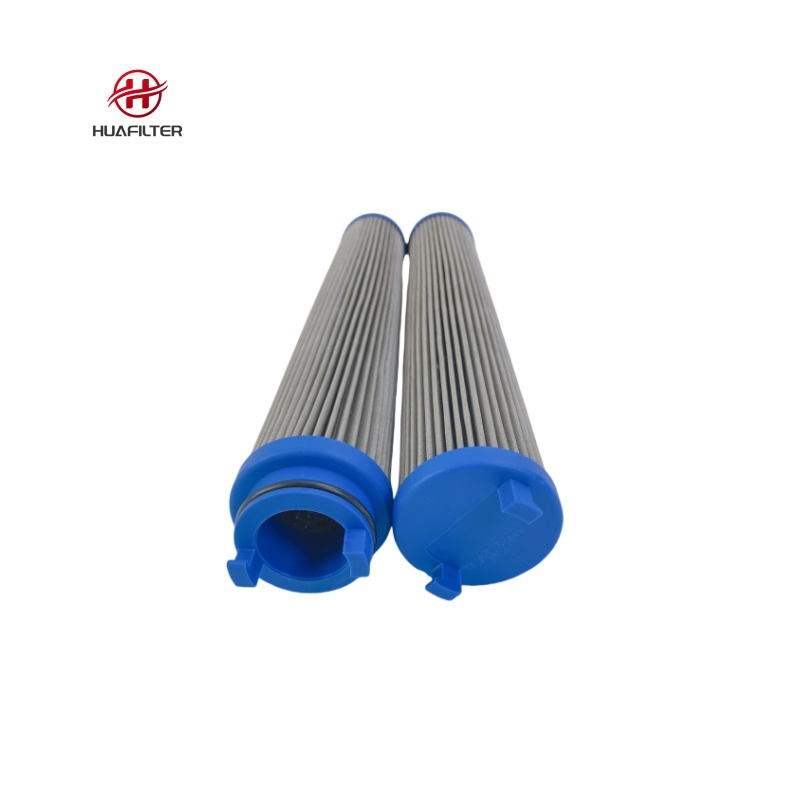

Contamination (80-90% of failures): Causes sticking. Solution: Clean valve, replace filters.

Wear and Tear: Causes leakage and noise. Solution: Replace seals and cores.

Leakage: Internal or external. Solution: Inspect seals and seats.

Preventive Tip: Always use clean fluid and high-quality filters.

Future Trends

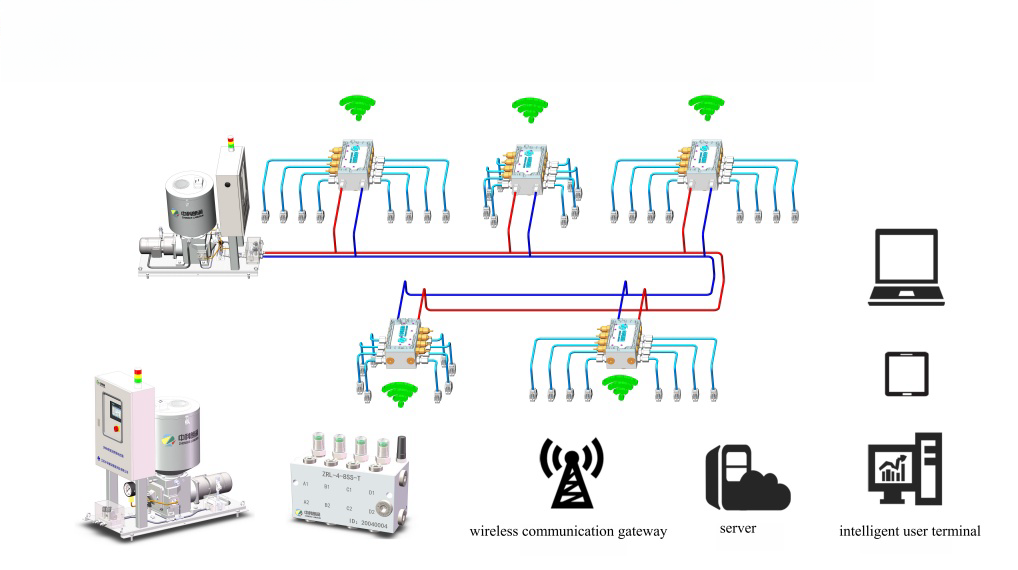

Smart Technology: Internet connectivity for remote monitoring and predictive maintenance sensors.

Electrification: More electric-operated valves for precise digital control and energy efficiency.

Advanced Materials: Stronger, lighter components resistant to various fluids.

Frequently Asked Questions

How Does a 2-Way Hydraulic Valve Work?

It uses a movable core (ball, disc, or spool) that either blocks or allows fluid flow between two ports.

Difference Between Solenoid and Manual Valve?

Solenoid valves use electromagnetic force for automatic, fast operation. Manual valves require human operation and are more cost-effective for simple tasks.

Can 2-Way Valves Control Flow Rate?

Yes, through pulse-width modulation (rapidly switching on/off), they can achieve variable flow control.

Conclusion

The 2-way valve might be simple, but it's essential for hydraulic systems. Whether you're stopping flow for safety, controlling a cylinder, or saving energy, these valves get the job done reliably and cost-effectively.

Understanding 2-way valves helps you choose the right valve, troubleshoot problems, and maintain equipment properly. Remember, the best valve is the one that matches your specific needs. When in doubt, consult with hydraulic professionals who can help you make the right choice.