Flow control valves are like the traffic lights of the industrial world. Just as traffic lights control the flow of cars on busy streets, these valves control the flow of liquids, gases, and steam in pipes and systems. Whether you're pumping water, moving oil through pipelines, or controlling air pressure in machines, flow control valves make sure everything moves at just the right speed and pressure.

What Are Flow Control Valves?

A flow control valve is a device that controls how much fluid flows through a pipe or system. Think of it like a faucet in your kitchen - you can turn it to let more or less water flow out. But flow control valves are much more precise and can work automatically without someone turning them by hand.

These valves have four main jobs:

Speed Control: They control how fast things move in hydraulic systems, like the arms of construction equipment.

Flow Distribution: They split flow between different paths, like dividing water to different sprinkler zones in your yard.

Flow Protection: They prevent too much fluid from flowing, which could damage equipment.

Pressure Control: They keep the pressure in systems steady and safe.

How Do Flow Control Valves Work?

The basic idea is simple: by making the opening smaller or larger, you can control how much fluid flows through. It's like putting your thumb over the end of a garden hose - the smaller the opening, the less water comes out (but it comes out faster).

Flow control valves work in several ways:

- Fixed Opening: Some valves have a set opening size that doesn't change.

- Variable Opening: Others can adjust their opening size based on conditions.

- Pressure Compensation: Smart valves automatically adjust to keep flow steady even when pressure changes.

- Electronic Control: Modern valves use computer signals to make very precise adjustments.

Types of Flow Control Valves

By Compensation Method

Non-Pressure Compensated Valves

These are the simplest type. They have a fixed or adjustable opening, but the flow changes when pressure changes. They work best when system pressure stays fairly steady. They're cheap and simple but not very precise when conditions change.

Pressure Compensated Valves

These valves are smarter. They have special parts that automatically adjust the opening to keep flow steady even when pressure changes. They're accurate to within 3-5% and work great when system pressure goes up and down a lot.

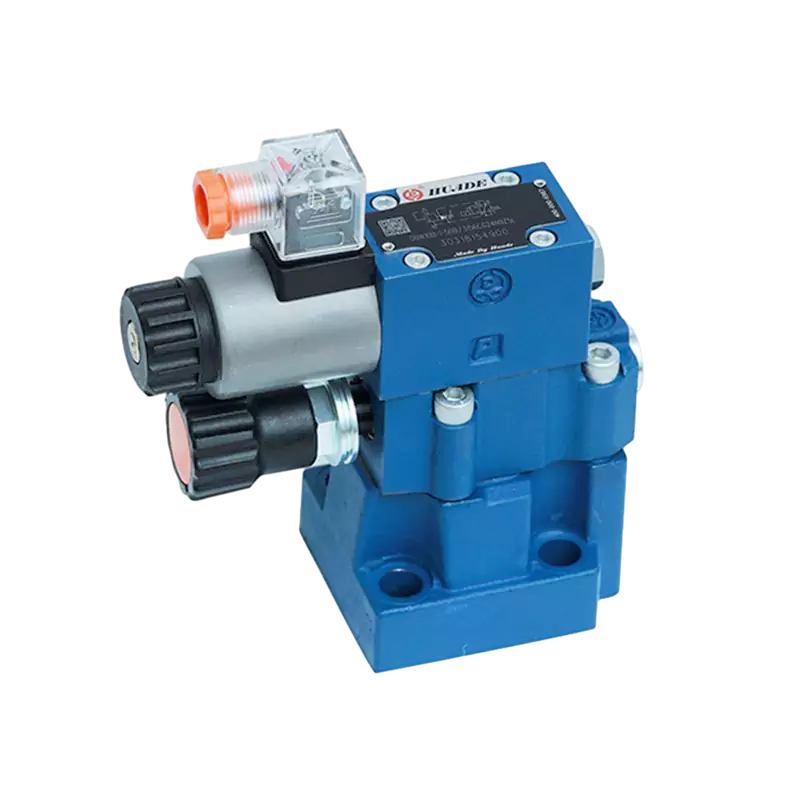

Pilot-Operated Valves

These use a small "pilot" valve to control a larger main valve. They're very responsive and work well for high-flow applications where you need quick changes.

By Structure Type

Ball Valves

These have a ball with a hole through it. When you turn the ball, you can open or close the flow path. They're great for quick on/off control and seal very well. You'll find them in oil refineries and heating systems. However, they're not the best for fine flow control.

Butterfly Valves

These have a disk that rotates to control flow. They're lightweight and create little pressure drop. They work well for large pipes and water systems. They're compact but don't seal perfectly at high pressures.

Needle Valves

These have a pointed needle that fits into a cone-shaped seat. They give very precise control and are perfect for small, accurate adjustments. You'll see them in laboratories and analytical equipment. They're very precise but only handle small flows.

Globe Valves

These are workhorses of flow control. They have good flow control ability and work in many applications like chemical plants, power plants, and oil refineries. They create more pressure drop but give excellent control.

Gate Valves

These have a flat gate that slides up and down. When fully open, they create very little pressure drop. They're mainly used for on/off control, not flow control. You'll find them isolating sections of pipe systems.

Diaphragm Valves

These use a flexible diaphragm to control flow. They seal perfectly and resist corrosion well. They're perfect for pharmaceutical and food processing where you can't have any leaks. They have pressure and temperature limits.

Pinch Valves

These squeeze a flexible tube to control flow. They're economical and great for handling slurries with solid particles. Mining and wastewater treatment plants use them often. They're cheap but have pressure and temperature limits.

By Actuator Type

Pneumatic Actuators

These use compressed air to operate the valve. They're reliable, fast, and economical. They work great where there's no electricity available and can cycle millions of times. However, they have limited power and shorter life than other types.

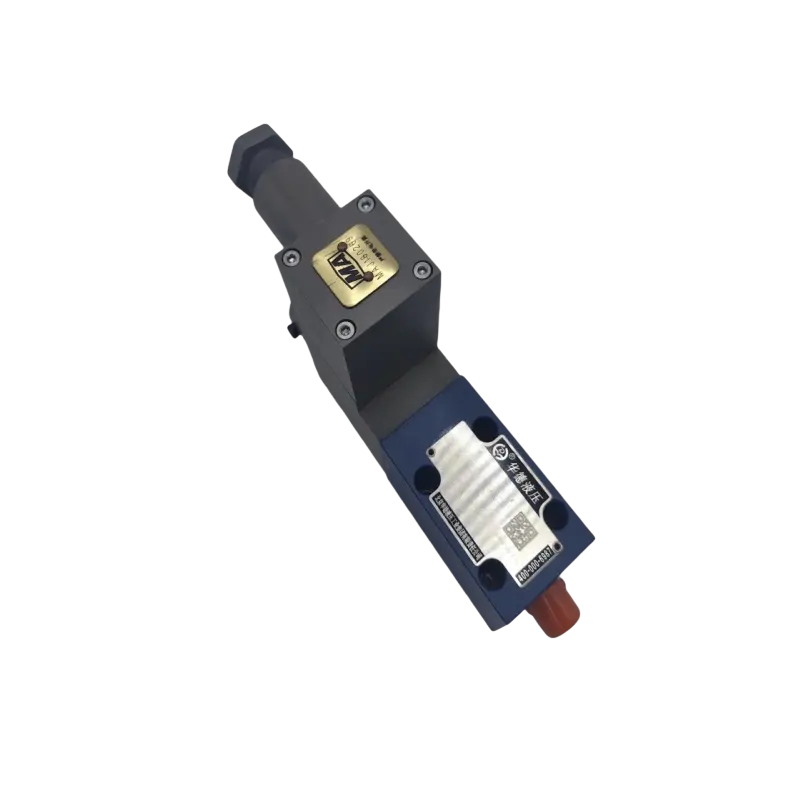

Electric Actuators

These use electric motors (AC or DC) to operate valves. They're very efficient, clean, quiet, and precise. You can control them remotely and they save energy. They cost more initially and can overheat with frequent adjustments.

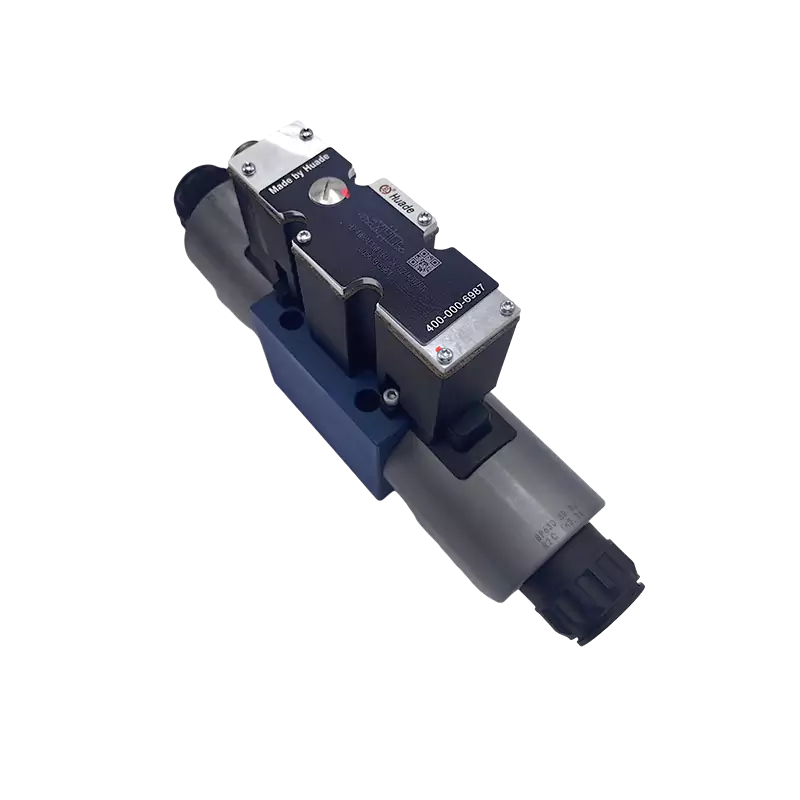

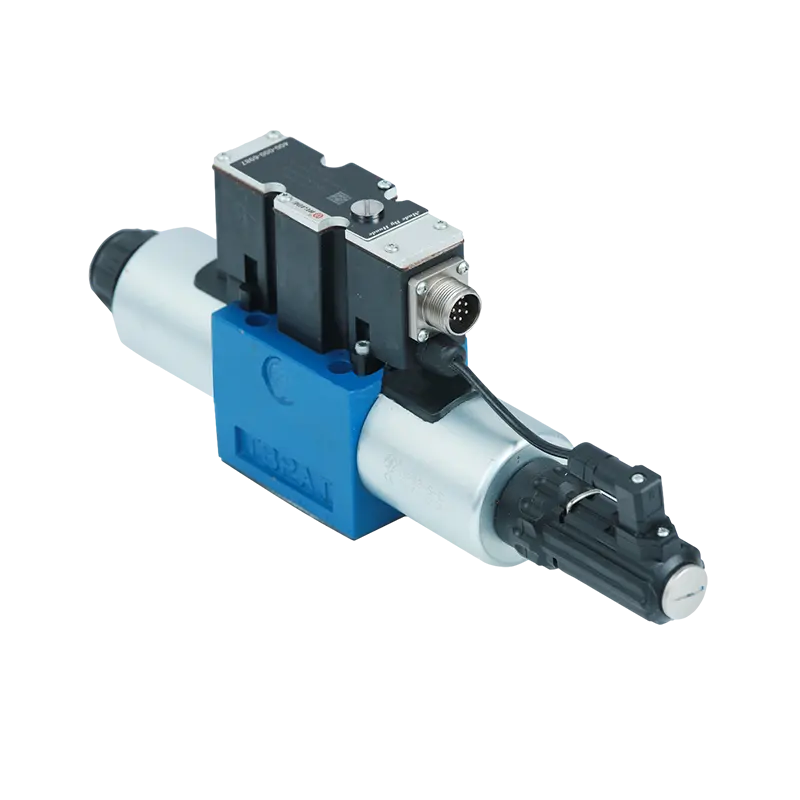

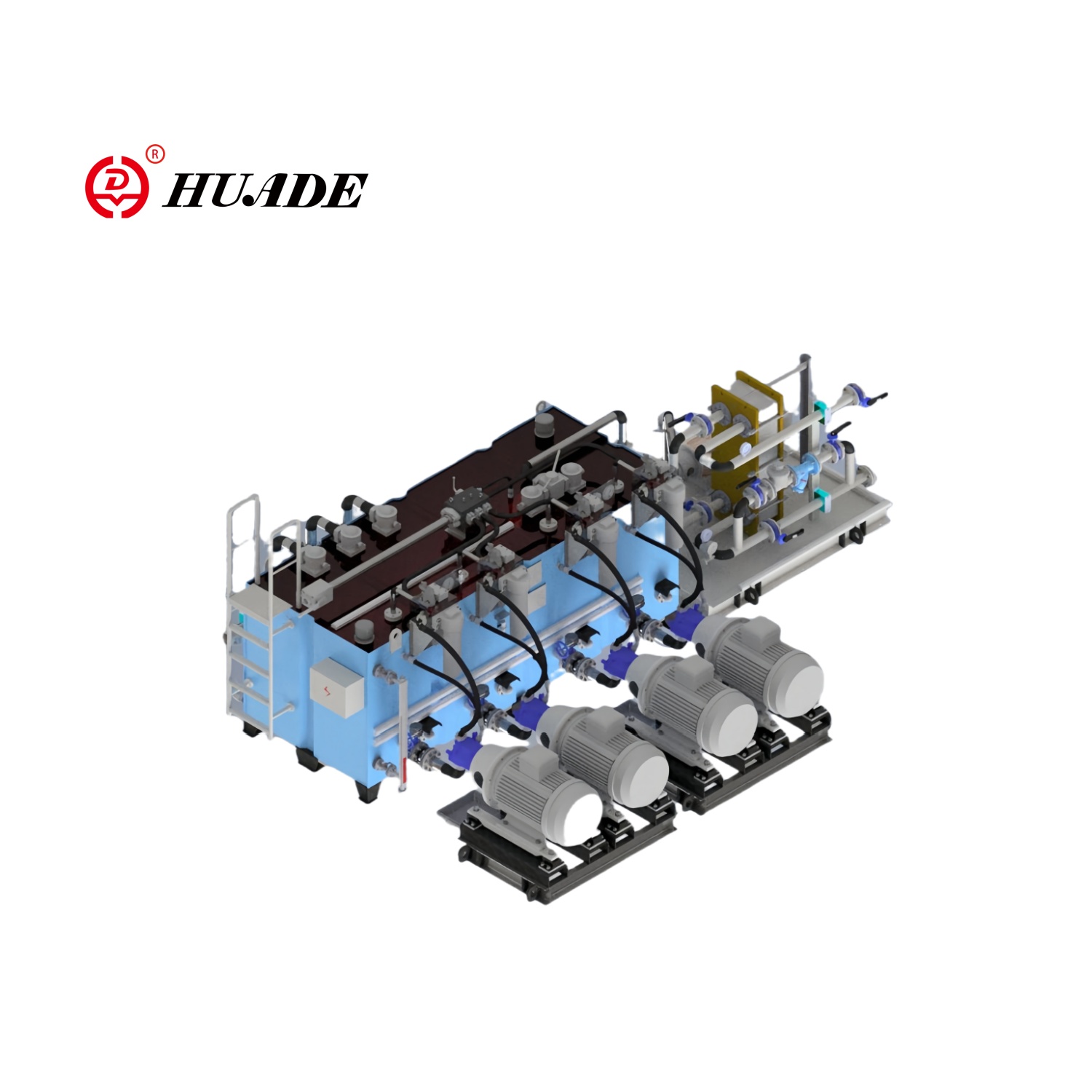

Hydraulic Actuators

These use hydraulic fluid for power. They produce very high force and last a long time. They're perfect for heavy-duty applications but create complex systems with potential leak risks.

Where Are Flow Control Valves Used?

Hydraulic Systems

In construction equipment like excavators and bulldozers, flow control valves control how fast the arms and buckets move. They also distribute hydraulic power to different functions and keep system pressure safe.

Pneumatic Systems

In air-powered systems, these valves control how fast air cylinders extend and retract. They prevent jerky motion and reduce wear on equipment.

Oil and Gas

Control flow in pipelines, manage liquid levels in separation tanks, and regulate pressure throughout systems.

Water Treatment

Distribute water throughout cities, prevent overconsumption, and control treatment processes.

Chemical and Pharmaceutical

Precisely mix ingredients, control reaction rates, and maintain product quality.

Manufacturing

Control speeds in automated equipment, manage hydraulic presses, and coordinate multiple machine functions.

Food and Beverage

Control ingredient flows, manage temperatures, and maintain sanitary conditions.

Special Environments

- Corrosive Environments: Use special materials like stainless steel to resist chemical attack.

- Explosive Areas: Use explosion-proof designs certified for hazardous locations.

- High Temperature/Pressure: Special designs handle extreme conditions safely.

- Sanitary Applications: Meet strict cleanliness standards for food and drug production.

Flow Control Valve Sizing Calculator

How to Choose the Right Flow Control Valve

Choosing the right valve is like choosing the right tool for a job. You need to consider several factors:

Fluid Properties

- What type of fluid: liquid, gas, or steam?

- How thick (viscous) is it?

- Is it corrosive or clean?

- What temperature range?

- What pressure levels?

Performance Requirements

- How much flow do you need (minimum, normal, maximum)?

- How accurate does control need to be?

- How fast must it respond to changes?

- What's the adjustment range needed?

System Integration

- What pipe size and type?

- How will it connect (flanged, threaded, welded)?

- What type of actuator (air, electric, hydraulic)?

- What control signals (analog, digital)?

Environmental Conditions

- Operating temperature and humidity

- Safety requirements (explosion-proof, fire-safe)

- Maintenance accessibility

- Cost considerations (initial and operating)

Flow Characteristics

Most valves have one of these flow patterns:

Linear: Flow increases steadily with valve opening - good for simple applications.

Equal Percentage: Flow increases exponentially - used in 90% of applications because it gives better control.

Quick Opening: Small movements create big flow changes - used for on/off applications.

Maintenance and Troubleshooting

Like any mechanical device, flow control valves need regular care to work properly.

Common Problems

Flow Issues

- Inconsistent flow usually means dirt, wear, or wrong adjustment

- Low flow often indicates blockages or worn parts

- Fluctuating flow suggests pressure problems or unstable control signals

Leakage Problems

- External leaks come from worn seals or loose connections

- Internal leaks happen when valve seats wear out or debris gets caught

- Packing leaks occur when seals around the stem get old

Performance Issues

- Sticky operation suggests corrosion, debris, or lack of lubrication

- Slow response indicates actuator problems or control signal issues

- Excessive noise usually means cavitation, vibration, or turbulent flow

Maintenance Strategy

Preventive Maintenance

- Check monthly for leaks, wear, and corrosion

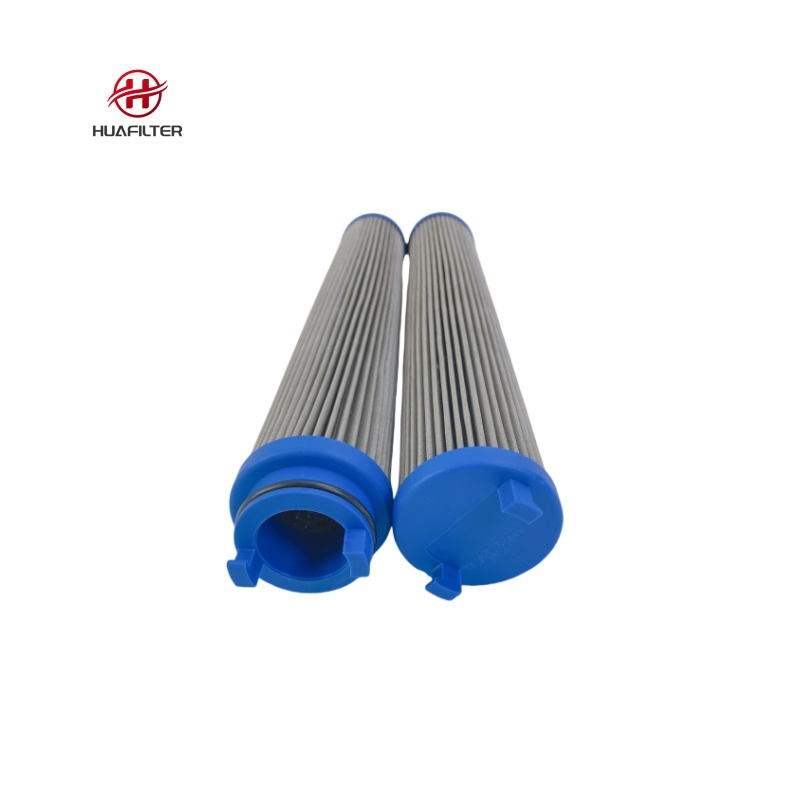

- Test hydraulic fluid and filters quarterly

- Lubricate moving parts regularly

- Calibrate and test performance periodically

Condition Monitoring

- Use pressure gauges to detect blockages or wear

- Monitor flow rates to identify performance changes

- Watch temperatures to prevent damage

- Analyze vibration to catch mechanical problems early

Troubleshooting Process

- Check each component systematically

- Find the root cause, not just symptoms

- Verify performance after repairs

- Keep detailed maintenance records

The Future of Flow Control Valves

Technology is making flow control valves smarter and more efficient.

Smart Valve Technology

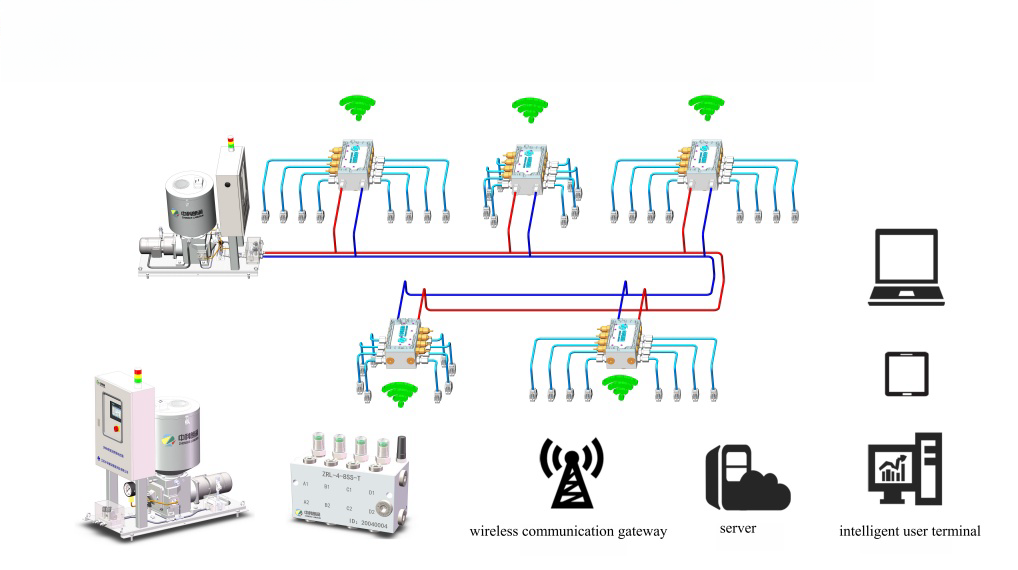

Internet of Things (IoT) Integration

Modern valves include sensors for pressure, temperature, flow, and vibration. They collect data continuously and can be monitored remotely through smartphones or computers. Cloud-based systems analyze this data to provide optimization suggestions.

Artificial Intelligence Applications

AI algorithms can predict when valves need maintenance before they fail. They automatically adjust valve settings based on changing conditions and can detect unusual operating patterns that might indicate problems.

Digital Twin Technology

Engineers create virtual copies of physical valves that simulate performance and allow testing in virtual environments. This helps optimize designs and train operators without risking real equipment.

Industry 4.0 Integration

System Connectivity

Modern valves communicate using industrial networks and process data locally for faster response. They integrate seamlessly with manufacturing execution systems and use standardized communication protocols.

Increased Automation

Systems operate with minimal human intervention, coordinate multiple valves automatically, and optimize their own performance. They can even diagnose and recover from certain failures automatically.

Sustainability Trends

Energy Efficiency

New designs recover energy from pressure differences, reduce system energy consumption through precise control, and optimize entire systems for maximum efficiency.

Environmental Requirements

Stricter regulations demand lower emissions, sustainable materials, better recycling programs, and greener manufacturing processes.

Real-World Success Stories

Oil and Gas Industry

A major pipeline company installed smart flow control valves that eliminated manual maintenance for five years while maintaining precise control of multi-phase fluids.

Water Treatment

A city water system used 24-inch pressure-reducing valves to protect their distribution pipes while maintaining consistent water pressure throughout the city.

Manufacturing

An automotive assembly line improved production accuracy by 15% after installing pneumatic flow control valves that precisely controlled robot movements.

Learning More About Flow Control Valves

If you want to learn more about flow control valves, here are some great resources:

Online Learning

- Educational YouTube channels offer detailed explanations with animations

- Manufacturer websites provide selection guides and technical information

- Industry associations offer webinars and technical papers

Professional Development

- Valve manufacturers offer training courses

- Engineering schools provide comprehensive programs

- Industry conferences feature the latest technology and applications

Hands-On Experience

- Visit trade shows to see equipment demonstrations

- Participate in factory tours when possible

- Join professional organizations for networking and learning opportunities

Flow control valves are essential components that keep our modern world running smoothly. From the water coming out of your faucet to the fuel flowing through pipelines, these devices ensure everything moves at the right speed and pressure.

As technology advances, flow control valves are becoming smarter, more efficient, and more environmentally friendly. They're integrating with digital systems, predicting their own maintenance needs, and optimizing performance automatically.

Whether you're an engineer selecting valves for a new system, a technician maintaining existing equipment, or simply curious about how things work, understanding flow control valves helps you appreciate the complex systems that support our daily lives.

The future of flow control valves is bright, with innovations in smart technology, sustainability, and system integration continuing to improve performance while reducing environmental impact. By staying informed about these developments and following best practices for selection and maintenance, we can ensure these critical components continue to serve us well for years to come.